What is the Role of Collaborative Robots in Manufacturing?

All manufacturing companies are gearing up their practices to automate part or all of their production lines. It might seem like a big immediate investment, but it is a long-term opportunity to save millions on production.

So, the best way to automate operations is by introducing collaborative robots in manufacturing. It is a valuable and efficient investment over the standard programmable robot.

According to Universal Robots, It consumes less space and energy to bring out the utmost work efficiency at affordable pricing. Collaborative industrial robots are rapidly replacing the need or lack of labor. They are also brought to action for speeding up the production line, in case of high demands.

If you are running a manufacturing business in California, then you must have an idea of the role of collaborative robots in manufacturing. It will help you derive the best potential out of them.

What are Collaborative Robots in Manufacturing?

You must get an insight into the ideal implementation of these collaborative robots before you invest in them. It is because this is a disruptive technology, the understanding of which is pretty much limited among the few industries that are using them.

But, before you go ahead with the role or applications of collaborative robots, you must understand their operational efficiency.

Collaborative robots differ from industrial robots in terms of flexibility. You can easily reprogram the cobots to make them perform different tasks around the manufacturing or production line, and deal with various types of products.

Unlike industrial robots, you won’t have to go through complex scheduling or automation aspects for the cobots.

Collaborative robots were introduced to various industries because the production tasks demanded agility with an increasing supply ratio. And industrial or traditional robots couldn’t offer that, which compromised the production pace.

The easy definition of collaborative robots goes like this: it is a method that promotes direct physical interaction between a manipulator and a person. It was designed to work alongside humans on production or manufacturing lines in the same area, without any probable risks.

Role or Applications of Collaborative Robots in Manufacturing Sector

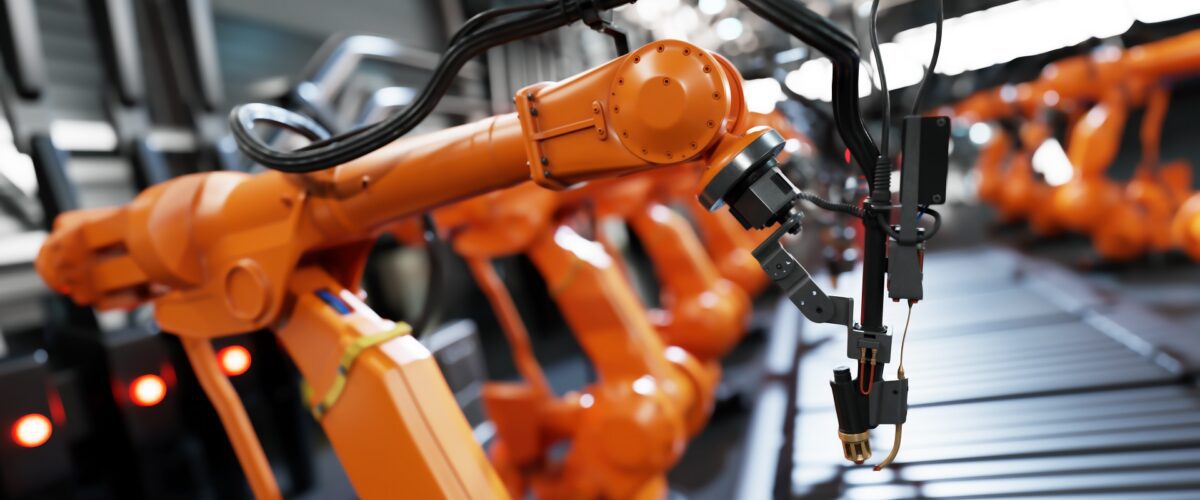

In every manufacturing process, transforming the materials into components is one of the major steps. And this process of finishing the products is carried out on the assembly lines.

Collaborative robots, being the best innovation in the robotics era, is now part of key development in the manufacturing sector. As the cobots are embedded with AI, Machine Learning, various sensors, and neural networks, their interactive potential with the surrounding environment has enormously improved.

To be precise, collaborative robots have vision, force, torque, and contact sensors integrated into their system. But where do we use them the most, and in what industries?

Here are some of the common roles that a collaborative robot plays in the manufacturing sector:

1. Use in Automotive Industry

Collaborative robots for automotive manufacturing are one of the most preferred applications of it. The flexibility of these robots is not the only reason for this industry to opt for cobots; the intention is also to release the employees from health-damaging and strenuous industrial activities.

The companies using cobots for their automotive manufacturing have reported a reduced cost of manufacturing, each car. Cobots work towards automating the repetitive assembly line tasks of the manufacturing process. In the automotive sector, cobots are used for welding, assembly, painting & coating, and quality assurance applications.

2. Use in Electronics Industry

Product testing and quality control are common applications of cobots in the electronics industry. Collaborative robots in this field are enabled to install chips in the testing machines and sort them in a specified manner.

Apart from that, a cobot is also automated within the industry to test the touchscreen devices and solder the PCBs. It is possible because of the built-in sensors, which allow the cobots to work precisely and delicately on fragile electronic parts. As a result, the margin of error is reduced.

3. Use in Food & Packaging Industry

With the advanced development of collaborative robots, food items are now easily handled by them. The gripper technology of collaborative robots in manufacturing sector has helped it be implemented in the food industry as well. Some of the common applications of collaborative robots in the food industry are palletizing, pick & place, and logistical automation. Hence, the overall food manufacturing and packaging process becomes easier by automating the tasks with the use of these robots.

4. Use in Laboratory

In laboratories, collaborative robots are preferred for machine loading, pipette dispensing, and refilling dispensers. In laboratories, it is possible to link a cobot to the database and automate small & repetitive tasks.

Parting Words

If you are running a manufacturing unit for any of the industries in California, and are still missing out on integrating collaborative robots, then you are losing your production efficiency.

So now that you are aware of what collaborative robots are, you know they can not just ease your task, but will also help you ensure safety, profitability, and increased production in the long run. If you want to get started with its integration, then connect with KVM Automation today in California. Irrespective of the industry you belong to, we will help you embed the power of automation into your manufacturing applications with our robotic system integration services.