What is Industrial Automation & Its Features in 2023?

Manual operations in various industries were proficient to a certain extent. But, as the demand increased, the supply had to pick up the pace. And with just manual operations, it was difficult for the industries to cope. Therefore, industrial automation was introduced!

What is industrial automation? It is a process in which the operations within a working premise are automated with technology and coded functions. The machines or equipment in this automation process don’t need direct human involvement.

With the introduction of these advanced technologies, it is now easy to manage and control the flow of resources, materials, and information in most of the production processes within an industry.

Let’s learn about industrial automation, its features, and how it will be utilized in 2023.

Fixed, Programmable, Flexible & Integrated Type Industrial Automation

Before we talk about the features of industrial automation solutions, let’s discuss the four types of it. If you go out and talk to several industries and ask them, what is industrial automation? They will tell you about how productive these solutions are and how they have generated higher revenues over time.

But, every industry prefers a specific industrial automation type that serves the right purpose. So, let’s understand the differences between fixed, programmable, and flexible types of industrial automation:

Fixed Industrial Automation

It’s also called hard automation, which is mostly preferable only for automating repetitive tasks using specific equipment. When you set up a fixed industrial automation solution, it becomes difficult to modify or reconfigure the process later.

If your production rate is consistent and the business needs stable output, then hard or fixed automation should be your pick. The assembly lines in the automobile industry are an example of fixed industrial automation.

Programmable Industrial Automation

If your industry deals with product batches, then programmable automation can streamline the process better.

The instructions fed to the automation equipment can be re-programmed depending on the varying batch of products that are being manufactured.

The control program will then function differently for each batch per the instructions and processing operations. It is the best pick for low or medium-volume operations. Therefore, this automation solution is implemented mostly in industrial robots.

Flexible Industrial Automation

The drawback with programmable automation was that the program or instructions were manually re-configured to operate for different batches. But, with flexible automation, all the specifications for different product batches can be pre-programmed to the control system.

As a result, the configuration change for the automation system will be quick and without manual intervention. It will save a lot of production time and enhance output efficiency. The best example of flexible industrial automation is CNC machines.

Integrated Industrial Automation

You will integrate the devices and equipment into a unified PLC control system in such an automation system. Hence, the production lines and processes will be linked to one another. It is a progressive approach toward streamlining the manufacturing process.

It is highly in demand with the growth of IIoT and Industry 4.0. The production lines and independent machines can now communicate through a network of automation, which ensures flexibility of in-demand manufacturing, with provision for customization.

Features of Industrial Automation

Now that you know what industrial automation is, it is time to understand the features and their advantages in productivity. The features include:

Keeps Your Plant Running 24/7

Even though you plan on hiring many workers to complete three shifts a day for running your plant, you will still have to shut it on holidays or for maintenance work. Hence, this will trigger downtime, and there will be financial losses.

PLC industrial automation can ensure that your manufacturing plant can continue doing its job 24/7 and throughout the year without a break. As a result, your plant will have less or no downtime or production halts.

There is a rare need to halt the automation system for maintenance, as any possible errors can be diagnosed without shutting it off completely. As a result, the productivity factor increases for your business.

Easily Programmable

The programmable and flexible industry automation systems can be easily configured to perform almost any task within the equipment’s capability boundaries. There is no need for any additional training that a human operator needs. As a result, the manufacturing process becomes flexible and faster.

Moreover, as automation systems can be programmed, it eliminates the possibility of human errors. It maintains uniformity in delivering quality outputs at all times.

Records Automation Data

When you enable the industrial automation data collection feature, you are open to acquiring vital production information and working towards improving its accuracy of it. Moreover, it will reduce the overall cost of collecting data.

Using this data, you can decide how to reduce industrial waste and improve your existing processes for added productivity. After that, critical data is also sent to the connected users via notification for immediate response.

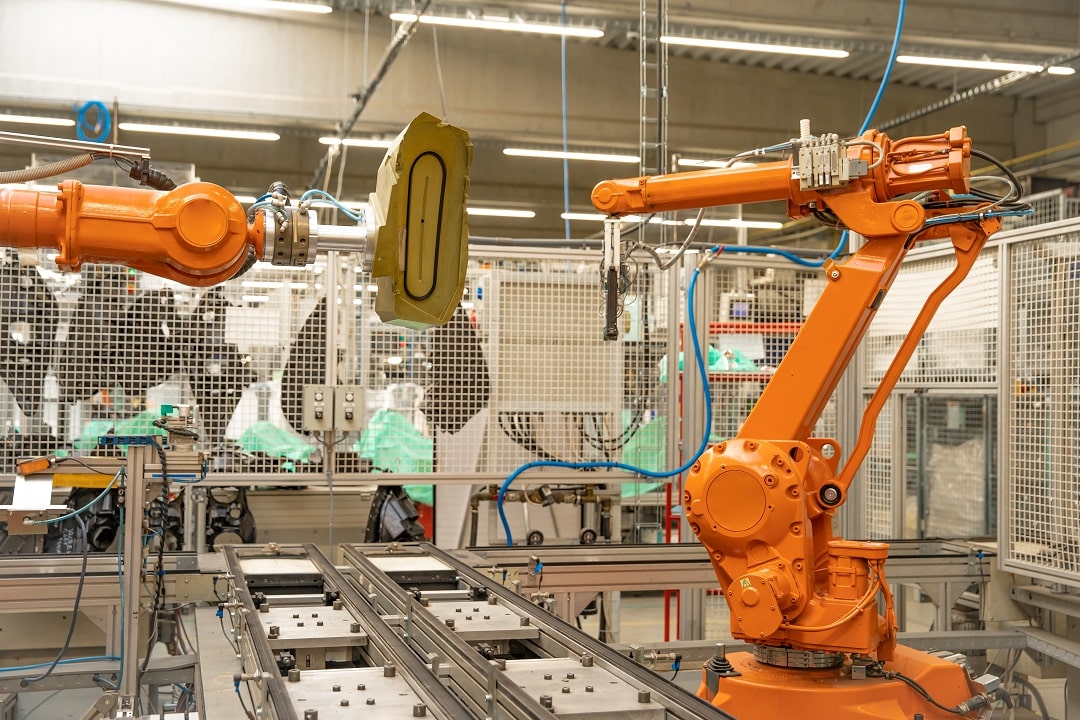

Ensures Employee Safety

With the introduction of robot equipment, employees are now safe from dealing with highly complex and hazardous jobs within the factory or plant. Some of such tasks involve lifting heavy weights, repetitive motions, dealing with chemical infusions, and others.

The codes are programmed to eliminate human intervention from complex or hazardous areas of operation. Hence, the safety aspects are achieved.

Conclusion

Industrial automation is the trend of business growth in all manufacturing plants. So, it is better to get an insight into its adaptation and features. Suppose you are starting a new manufacturing plant or are willing to upgrade your existing workforce. Industrial automation might be your perfect leap to increased productivity.

Connect with us at KVM Automation in Santa Ana, California. Let us help you automate your machines and devices to work connectedly to improve productivity in your manufacturing processes. We have expert solutions to accommodate all of your requirements.

References:

https://www.industlabs.com/news/industrial-automation

https://blog.phoenixcontact.com/marketing-sea/2017/05/automation-and-iiot/