What are the different types of plc & their usages?

PLCs are very powerful and popular tools and come in many different types. The types of PLCs are wide, and each has its application and function; therefore, if you wonder what the different types of plc & their usage are, read this article to the end.

We will introduce and review each of the different types of PLCs. Let’s look at the primary function and types of PLC and learn more about how it works.

What is PLC?

Before starting to introduce this product, it is good to spend some time examining its name and meaning. PLC is an abbreviation of an English term. P stands for Programmable here. This word means “programmable.” This section refers to the ability to program PLCs.

The letter l in this section stands for the word logic. This term indicates the logical analysis capability of PLCs. And finally, the letter c, which stands for Controller. These words are used for a specific reason and purpose in naming this product, which we will discuss in the following.

It is good to know that PLCs are a replacement for older products. These products are traditional control panels that have many disadvantages. Among these disadvantages, we can take as an example the dependence of their performance on magnetic relays. Another disadvantage of these panels is their dependence on industrial control timers.

Fortunately, PLCs were produced and launched to solve these problems. The main task of PLCs is to monitor the input of sensors constantly. PLCs must make decisions about the outputs by monitoring the data received from the sensors (the same as the input of the sensors).

<h2>The reason for the popularity of PLCs

The reason for this is the beneficial applications of these products. The advantages of using PLCs are many, and this has caused their great popularity. We can boldly say that PLCs are advanced artificial digital computers or even something higher than them.

PLCs’ advantages and positive features are their high strength, PED controllers, constant and continuous control and monitoring, ease of programming and programming, and their ability to count. And timers, having hardware that is easy to work with, and many more to mention.

What is a PLC system?

As we mentioned before, these products have replaced the traditional control panels, and they are responsible for monitoring the sensors’ inputs, controlling the outputs, and making decisions about them. Each PLC system needs three modules that we name and examine one by one in this section.

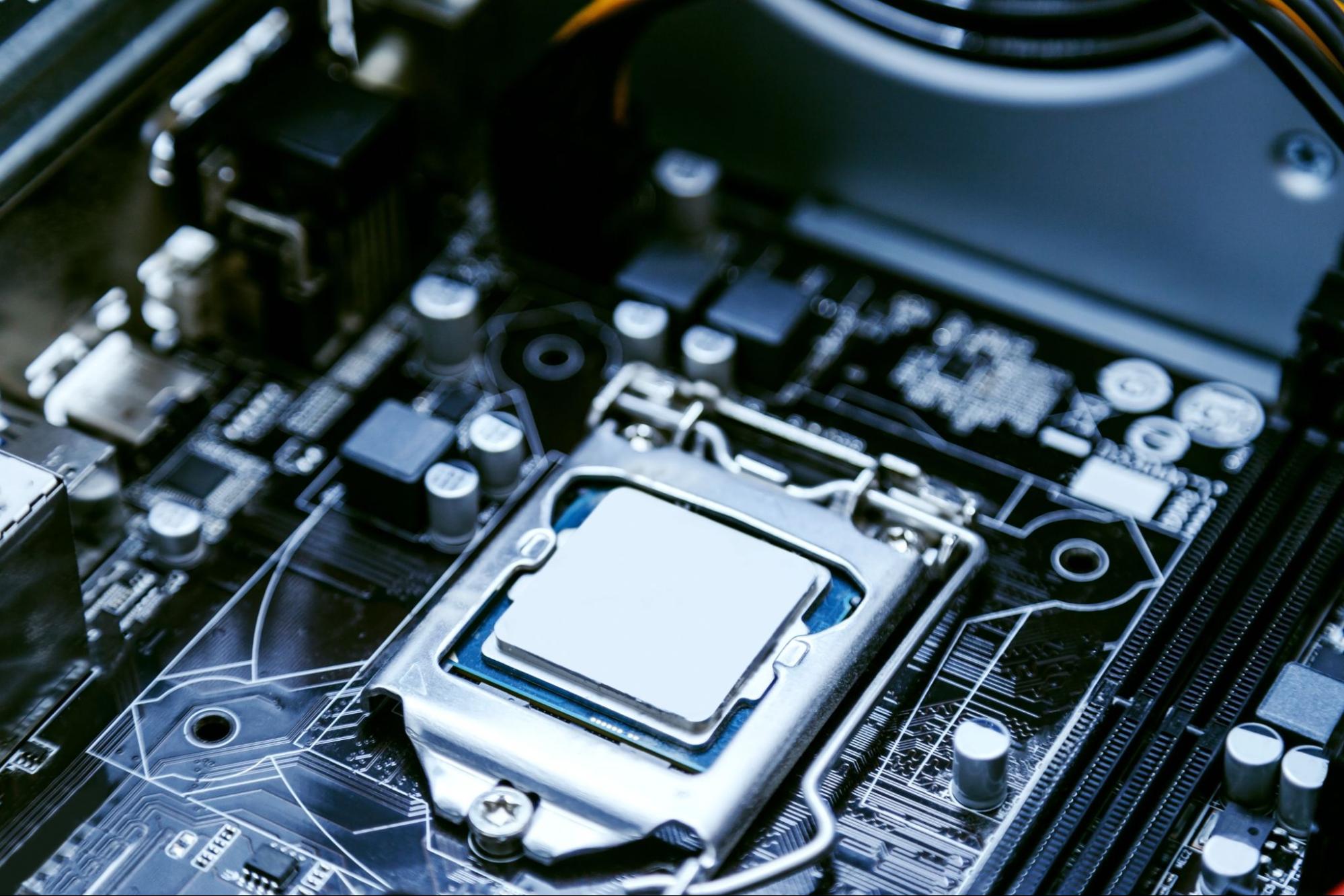

Processor module

The task of this department is very important. This module plays the main role and performs the main tasks.

The task of this module is to perform all necessary calculations. Therefore, any calculations that need to be done are assigned to this section. Among other tasks of the processor module, we can mention processing all input data. Also, this module should produce appropriate outputs according to the inputs and the information obtained from their processing.

The processor module has a central processing unit and also has memory. This memory has both ROM and RAM. Each of these two types of memory has its use. This difference in application is due to the differences between these two types of memory.

Among the differences between ROMs and ROMs, ROMs contain some applications, that is, they have an operating system and programs such as drivers. But unlike them, RAMs do not benefit from the program and the operating system, and the only thing they do is save work data or written programs.

With the processor module benefiting from the memory, one of the annoying problems is eliminated. By saving the written programs in the memories, there is no need to waste time reprogramming every time.

It should be noted that these memories need a power supply. Of course, the power supply they need is easily provided. They need batteries that can last a long time.

Power supply module

This module also plays a vital role in the PLC because if the power is not supplied, it is obvious that the system will not be able to function.

The main task of this module is to receive AC power and convert it to DC power. Because this type of electricity is required by the processors and the size of the parts of this system, such as input/output modules, it is good to know that depending on the type of PLC, different voltages must be generated and directed to other points.

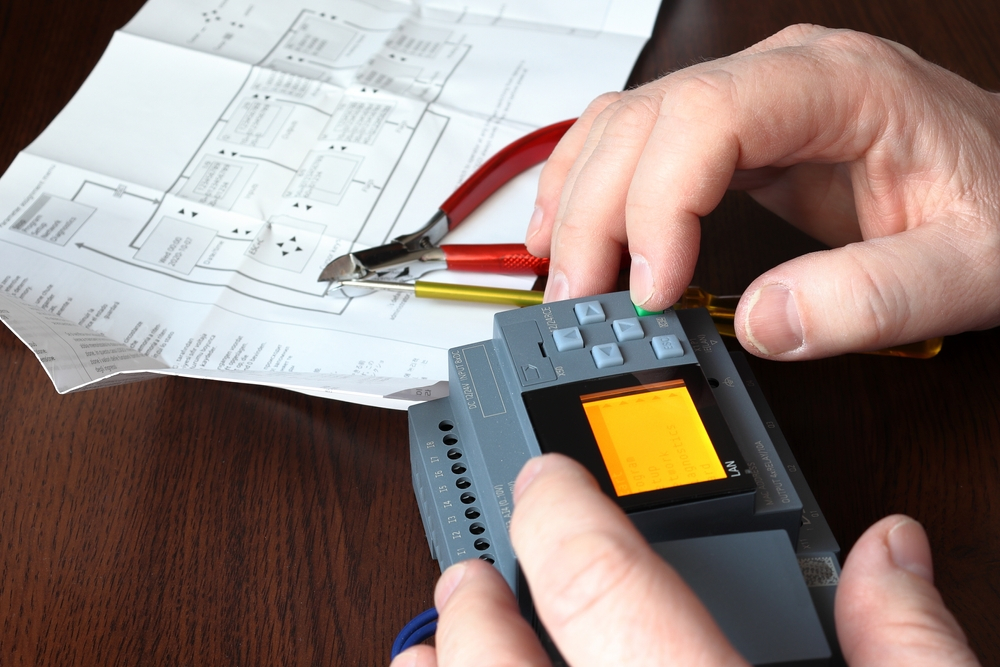

Input/output modules

The task of this module is to connect sensors and actuators with the system. What does it mean?

This means this module works so that the sensors direct them to the system to be examined and monitored as soon as they receive stimuli and data.

These stimuli can be temperature, pressure, different currents, etc.

It is good to know that input/output modules have many different types, each designed with a specific purpose and function.

In this section, we name some of these types and provide a summary of the characteristics of two of them:

a. Analog input/output module: This input/output module is designed to connect specific sensors and actuators. The sensors considered for this type of module are from the category of actuators that provide analog electrical signals. This module uses various equipment, including analog to digital converters. In this way, the analog signals become information that can be understood and analyzed for the system.

b. Digital input/output module: This module is helpful for digital stimuli. Among these stimuli, we can mention the on and off switch. These types of modules can receive different voltages, both Ac and Dc. According to the system and PLC type, these modules can have a certain number of inputs and outputs.

Types of PLCs

In general, different types of PLCs fall into four broad categories. In the continuation of this text, we will not only introduce and review these four categories in detail but also name some famous brands that produce PLCs and review them.

Mini PLCs

From the name of this category, it is clear that these types of PLCs fall under the category of small PLCs. Due to their small size, it is obvious that they have some limitations, among which we can point out that they benefit from fewer inputs and outputs. Due to their limits, these PLCs are unsuitable for large projects and more useful for small projects.

Compact plc

The unique feature of this type of PLC is exciting. The design of this type of PLC has been such that all parts and components, including inputs and outputs, processor, power supply, etc., are all placed in one box. Compared to mini-PLCs, compact or integrated PLCs are larger and can receive a broader range of input and output. (that is, 300 inputs and outputs, while this number is 40 for mini PLCs.).

It is good to know that these PLCs still need to be the biggest, and they are not suitable for large projects and can only satisfy medium projects.

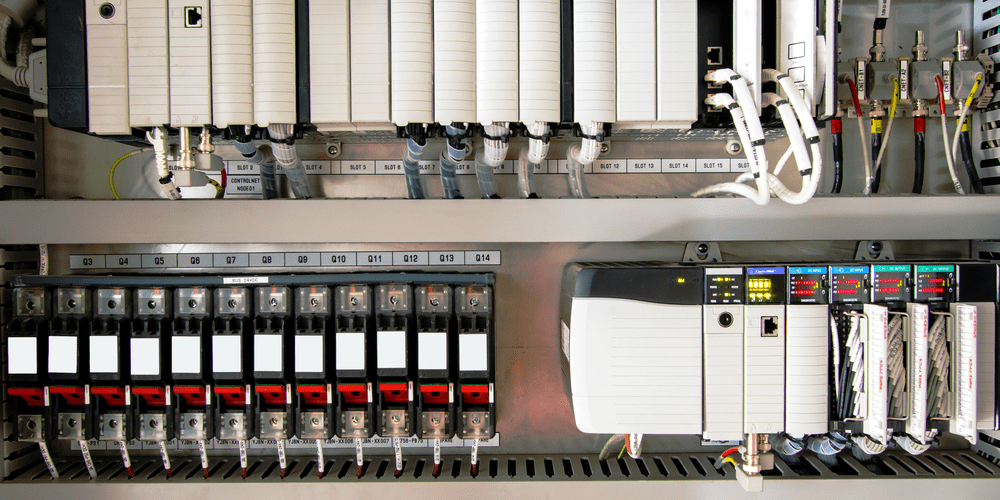

Modular plc

These types of PLCs also have very special features. In this type of programmable logic controller, important parts and components are separated! Of course, placing them next to each other is also possible.

Among the different features and advantages of this type of PLC, we can mention the ability to receive the number of inputs and outputs above them. This type of PLC can receive up to 2000 inputs and outputs. These types of PLCs need a frame to be closed on their end section before starting to work.

Rack plc

It is good to know that this type of PLC is very similar to the previous type, namely modular ones.

The special thing about these PLCs is that the inputs and outputs in this type of PLC are connected to the central module, which is located at the end of the PLC. This type of PLC can receive even more inputs and outputs.

This number reaches 5000 in this type of PLC. Therefore, it is obvious that this type is the most suitable type of PLC for large projects. Among the applications of this PLC, we can mention the projects of large refineries and petrochemicals.

Types of PLC brands

- · Allen Bradley PLC, or AB

An American company founded in 1903. We can safely say that this company is one of the largest PLC manufacturers in America and even the world.

- PLC Siemens

A German company founded in 1847.

- ABB PLC

A company resulting from the merger of ASEA Sweden and BBC Switzerland was established in 1988.

- Omron plc

The Japanese company was founded in 1933.

- Mitsubishi plc

The Japanese company was founded in 1921.

- Delta plc

The Taiwanese company was established in 1971.

- Fatek plc

The Taiwanese company was established in 1992.

- Kinco plc

The Chinese company.

- PLC LS

The Korean company was established in 1971.

In conclusion

This article introduced the PLC and types of Siemens plc and mentioned the various models for this brand, along with the features and characteristics of each one.

If you want to work in the field of PLC, you must familiarize yourself with the different brands that exist for it and acquire high skills in one brand.

Connect with KVM Automation today in California if you want to start its integration. Irrespective of the industry you belong to, we will help you embed the power of automation into your manufacturing applications with our robotic system integration services.