At some point, you’ve probably wished that you could monitor your production line from a remote location. But how is it possible with so many different equipment and processes involved? Fortunately, IoT remote monitoring solutions are designed specifically to help! We will explain what “remote monitoring” is and why it’s such an important part of your modern manufacturing.

What Is IoT Remote Monitoring & Control?

IoT Remote monitoring is a form of maintenance that allows you to monitor and control equipment from a distance. You can do this from anywhere with an active internet connection or even through your mobile device. This kind of remote monitoring provides multiple benefits over other forms of maintenance:

- It’s more secure than other forms because it reduces the risk of human error. There’s no need for someone to go out and check on things physically; everything can be done remotely.

- It’s cost-effective—you don’t have to pay anyone overtime or waste resources on travel when something goes wrong because they’ll be able to fix it without needing to leave their desk!

- It takes less time than traditional methods so that technicians can complete their jobs faster overall (and get back home earlier).

Total IIoT Solutions

When complex industrial automation calls for an innovative approach either for the control system, predictive maintenance or process optimization, bring in KVM Contractor as a solution.

Make Your Life Easier With Remote Monitoring Software

IoT Remote monitoring software makes it easy to monitor and control equipment at a distance. Not only that, but it’s affordable—you can use it on any device with an internet connection! There are more than a few reasons businesses choose IoT remote monitoring software over physical inspection.

Remote monitoring is widely used in industrial settings because it helps control costs and improves productivity by making processes more efficient. It’s also useful for remotely managing complex systems or machines from the comfort of your desk or home office.

Turnkey Solutions

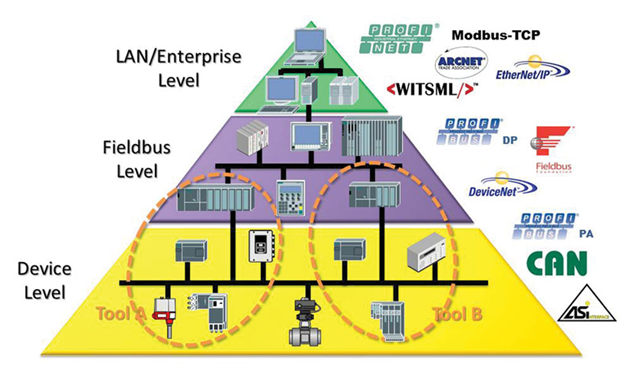

Suppose your control system depends on fine-tuned components while operating under harsh environmental conditions such as high temperature or absolute pressure. In that case, you need reliable and redundant systems to run your operation without any interruption. KVM Contractor is able to design a robust control system base on critical application level and redundancy. Our end-to-end solution includes all the layers of automation, from sensors to the supervisory station and remote monitoring(SCADA).

Some of our recent projects are listed as follows:

- Machinery condition monitoring

- Process automation and optimization

- Smart Power saving

- Soft sensors

- Remote monitoring

What Solution is Right for Me?

Our specialty is to build and practical solution from a concept design that is tailor-made as a turnkey project which meets all your requirements and can easily retrofit to your current existing system. for more information, please speak with one of our specialists to get started with the assessment.

Why Integrate a Total IIoT Solution?

Because a IIoT solution gives you the tools to optimize your operation. Whether it is temperature monitoring, power efficiency assessment, or evaluation of wear-and-tear on your equipment, predictive maintenance provides the means for your company to minimize equipment failure and replacement fees, lower energy costs, and increase part-life cycles.

What does this mean? That means that managers and technicians can have insight that helps them monitor and optimize their operation or process conditions more efficiently and save costs. It means that farmers in hydroponics or larger industrial farms can track the environmental conditions of their farms to fine-tune humidity, heat, and soil conditions for higher crop yields. Finally, it means HVAC specialists in industrial settings can maximize the lifetime of their equipment through predictive maintenance so pumps last longer, machines run at optimal capacity and the necessity for part replacement due to wear decreases exponentially.

Predictive maintenance means getting ahead of potential problems and saving time, money, and effort on repair and replacement.

Cloud automation

Keep Tabs on the Health and Efficiency of your Industrial Operations

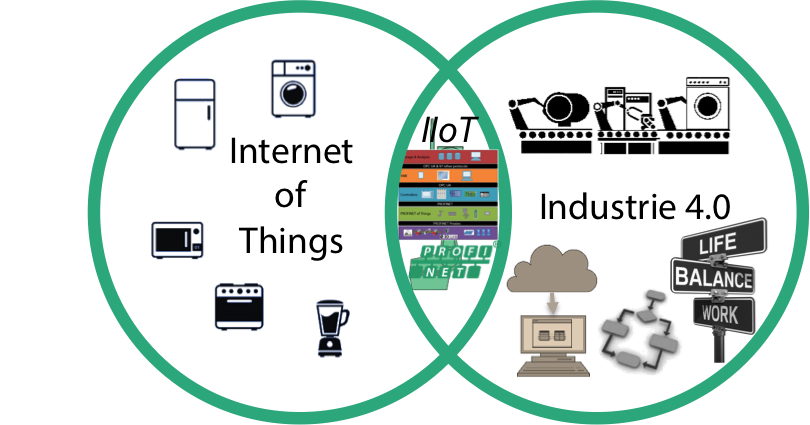

With the advent of the IIoT market, which is geared towards maximizing efficiency in the industrial 4.0 generation, the industry leaders are utilizing advanced hardware to monitor their operations from data-driven hydroponic farming to an industrial plant or simply a business that relies on the health and efficiency of its HVAC system. You will probably benefit from utilizing cloud HMI.

Wireless Data Communication

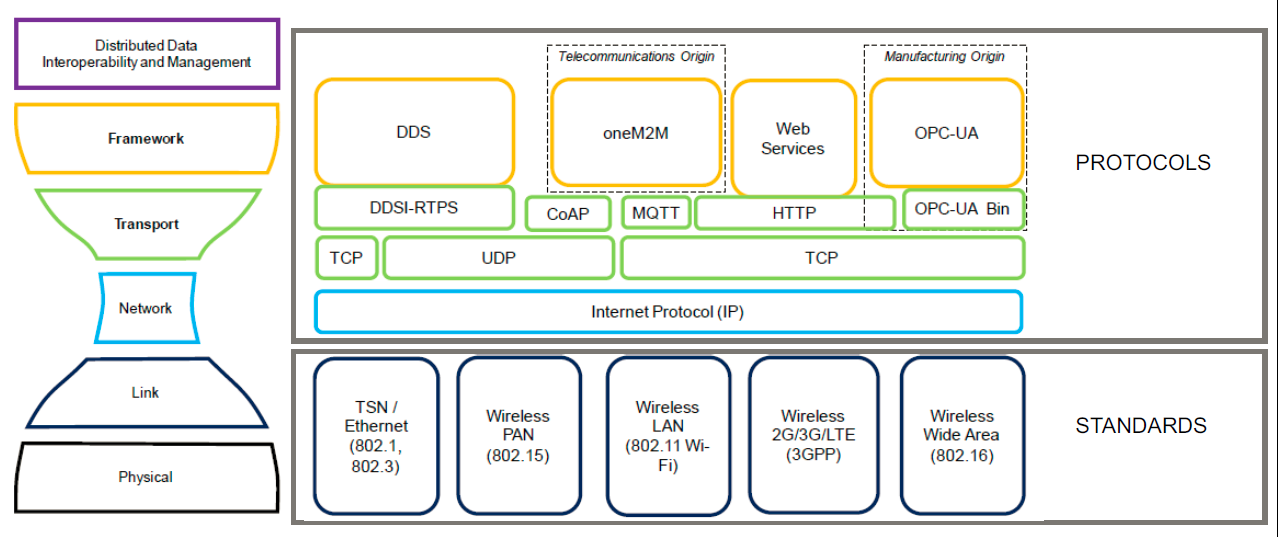

We provide a retrofit solution that relies on popular protocols which easily interface with different.

Devices and controllers such as:

- MODBUS TCP/RTU

- Ethernet/IP

- OPC UA

- Profinet

Our solutions offer you a 360-degree aggregate real-time monitoring system that could meet your required accuracy and efficiency.

Consultation and Implementation

KVM Contractors will offer you a new customized installation or retrofitted solution which is fit for your budget and current existing system either it is a SCADA PLC system or sequence panel.

IoT Remote Monitoring

Support Your Process with Advanced IoT Remote Monitoring

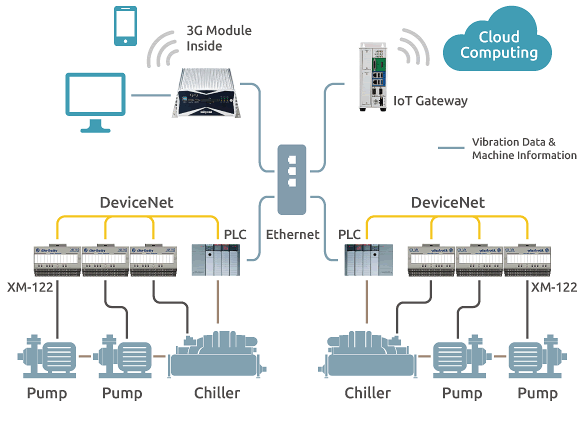

Our IoT remote monitoring solution is designed with reliable hardware and software components that meet any application reliability requirement and ensure that the connection and system are working as robust and redundant in any ambient condition. This solution usually comes with cloud services that help the user to access the live data logger from any safe connection.

In addition, our products, by default, monitor the ambient parameters and meta-data such as temperature, vibration, humidity, and barometric pressure.

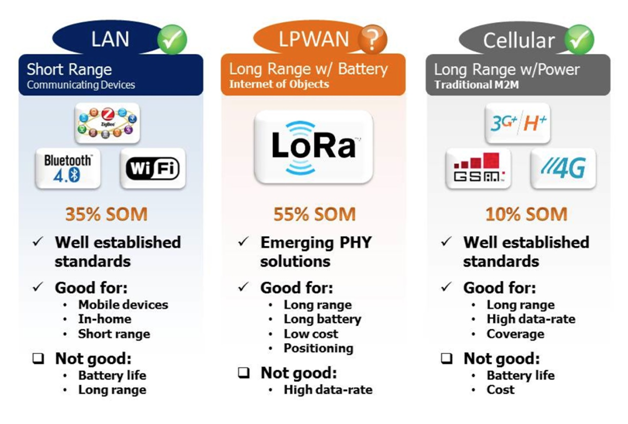

Either for the fog or cloud connection, depending on the nature of the project and availability, we are using different types of connection media, such as:

- 900Mhz P2P

- LTE-M

- SigFox

- LoRa WAN

- WiFi

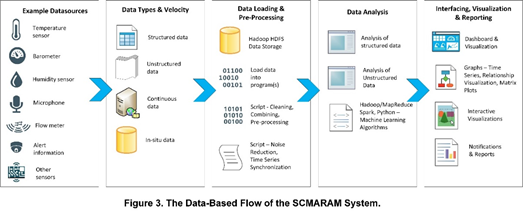

Our data loggers and modems are integrated into our custom SaaS(Software as a Service) to minimize the noises during DAQ (Data Acquisition) and smooth interaction with user control interfaces and sequence control panels.

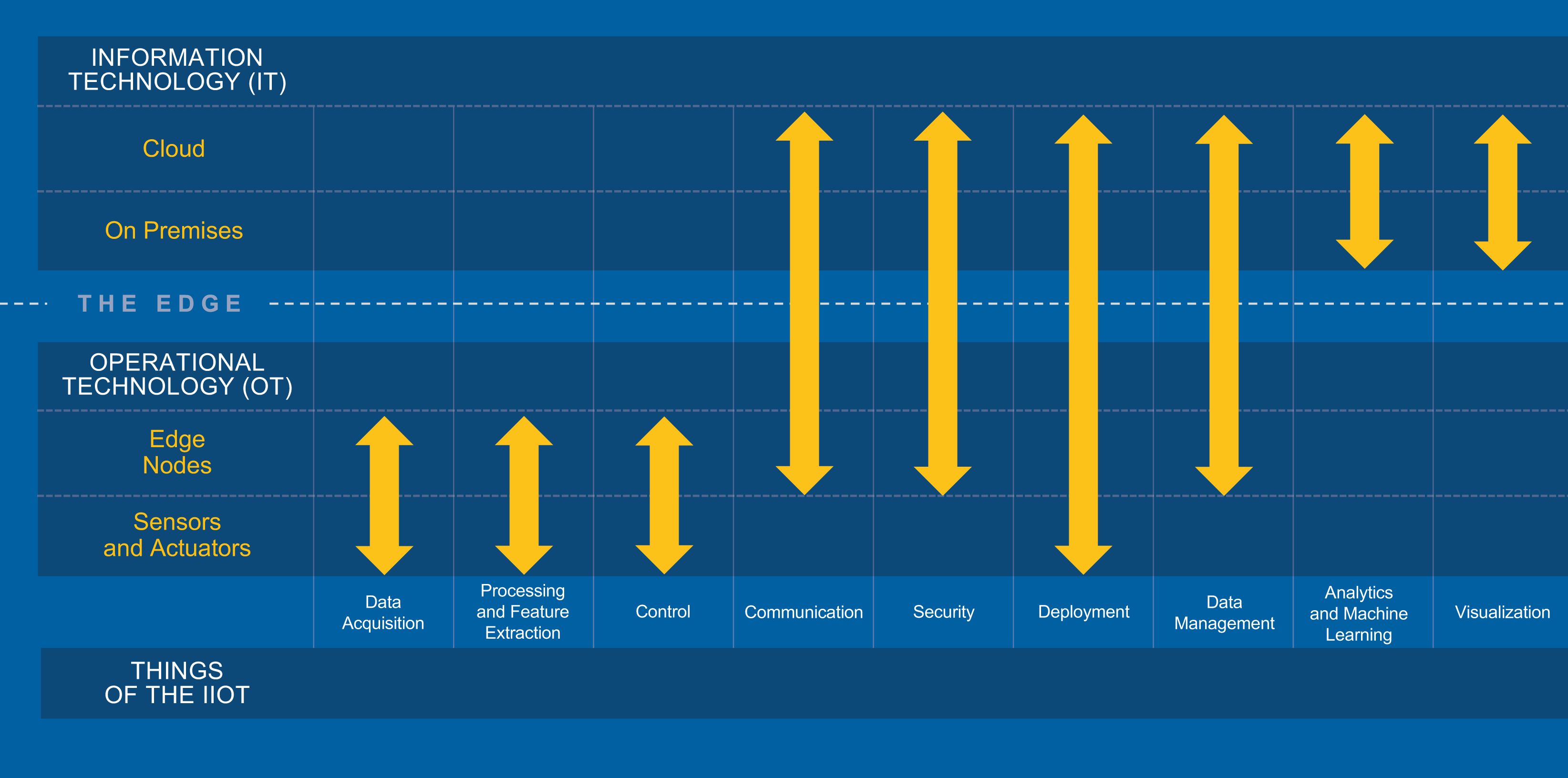

KVM Contractor utilizes Edge-Node Data processing and Feature Extraction to decentralize data processing throughout all monitoring solutions. The “edge” here is the gateway between your operational technology (sensors and monitoring hardware) and your informational technology (cloud processing, data visualization algorithms).

At some point, you may need to make adjustments and refine your production processes. Therefore, we use offline programming, which will allow us to create a digital twin of your software. With this, we can optimize cell design, reprogram existing cells, and test changes to ensure efficiency without disrupting production.

Real-time IoT remote monitoring can lead to better decision-making

The main advantage of real-time remote monitoring is making better decisions. For example, utilities can detect a power outage and restore service faster, reducing customer inconvenience and energy usage. Similarly, operations managers can identify problems with equipment before they become serious issues—reducing downtime and maintenance costs for facilities in all industries.

According to Amazon, real-time remote monitoring with IoT enables companies to operate more efficiently, reduce costs and improve customer satisfaction.

Industrial IoT devices and sensors generate data when deployed

Industrial IoT devices and sensors generate data when deployed. Data is collected, transmitted and stored in the cloud by a gateway. Location and state of devices are managed by the cloud to ensure that critical data is delivered in real-time to users.

Data Engineering

Provide Machine Data to any Industrial Application

Our systems also provide the kinds of optimization that can help control your processes so that they operate with high efficiency. By using cutting-edge process control and advanced data analytics, which is based on data visualization, and machine learning through the vendors like IBM, National Instrument, or Siemens, your process will have a responsive solution for handling your industrial process. Put humans in control of making big decisions and leave the process management with our intelligent systems.

KVM Automation data integration solution offers a scalable and reliable way to integrate valuable PLC data into a wide range of applications.

Whether you are a machine builder or a machine user, KVM Automation helps you to easily integrate machine data into a centralized application for analysis and visualization without any duplication or data loss.

Industrial Automation and Data Historian

Monitor your machines directly from the web, anywhere, anytime.

With the advent of the IIoT market, which is geared towards maximizing efficiency in the industrial 4.0 generation, the industry leaders are utilizing advanced hardware to monitor their operation from data-driven hydroponic farming to an industrial plant or simply a business that relies on the health and efficiency of its HVAC system. You will probably benefit from utilizing cloud HMI, or a data historian software that records the data in the Could. Data historians are commonly used where reliability and uptime are critical. The programs are used to gather information about the operation of programs in order to diagnose failures. Some of the software that we recently used in our projects are OSIsoft PI System and Kepware.

Software Integration

Support your Automated Process with Data-Driven, Cloud-Based HMI

Regardless of your hardware setup and brands, your operation needs the best tools to gather, display, and analyze the data gained from either a decentralized system such as multiple controllers and remote I/O’s or centralized systems such as SCADA panel.

Data processing

Our systems also provide the kinds of optimization that can help control your processes so that they operate with high efficiency. By using cutting-edge process control and advanced data analytics which is based on data visualization, and machine learning through the vendors like IBM, National Instrument, or Siemens, your process will have a responsive solution for handling your industrial process. Put humans in control of making big decisions, and leave the process management with our intelligent systems.