Industrial Automation

Automation is the use of control systems to reduce or eliminate human intervention in a process. The control system monitors and directly manipulates an industrial plant, machine, or device. Industrial automation can be implemented at different scales: factory wide, process line, production unit and workcell.

The benefits of industrial automation include improved quality of products, reduced cost and time to market, higher productivity and minimization of material waste.

What is industrial automation?

Industrial automation is the use of control systems, computers and information technology to control industrial processes. It involves the use of electrical, mechanical, and electronic devices to aid in production. The main purpose of industrial automation is to increase productivity.

Industrial Automation Solutions

KVM Automation develops any project by using industry-standard instruments and hardware. Then, provide a creative and targeted approach for your control system through a centralized or decentralized industrial automation system. We use cutting-edge technology, such as the latest soft sensors and monitoring hardware devices that would fit your industrial processes and are rapidly deployed and rolled out.

Why Would You Need Industrial Automation?

Industrial automation is a process whereby machines are programmed to perform tasks or complete operations without human intervention. Industrial automation reduces the need for human labor, thereby reducing costs related to labor, such as employee benefits and wages, payroll taxes, and insurance. It also increases production efficiency by eliminating waste from repetitive manual processes.

Industrial automation also reduces human error in manufacturing processes by reducing the chance of operator error. In addition, industrial automation can increase product quality because it prevents product defects that occur due to improper materials handling or assembly line errors (due in part to fatigue). Finally, industrial automation may also improve safety at work by eliminating hazardous working conditions such as loud noise levels, extreme temperatures, or other potentially dangerous working conditions.

Types of Automation

The types of automation vary in level of sophistication and complexity. They include FMS, PLC, DCS, CNC, and robotics.

Flexible manufacturing systems (FMS) are computer-based production systems controlling many factory floor machines.

They consist of several stations with robots or people operating them to produce parts for an assembly line. Each station performs one step in the process; once it’s completed its task, it passes the part on to another station where another robot or human adds some more components before sending it off again until all necessary pieces have been added together; finally, they will be installed into whatever product they are made for!

Design Control Systems

KVM Automation ensures that the proper level of technology is used to meet the requirements of the process you need to control. Furthermore, since each process is unique to the company and industry, we provide custom solutions in automation that also offer excellent cost, quality, and safety. After all, we promise our clients a return on potential investment by utilizing our solution.

KVM cultivates knowledge based on engineering and automation expertise. We are combining different brands and protocols of PLC, HMI Software, and other control devices from reputed manufacturers to achieve the best results and outcomes for our projects.

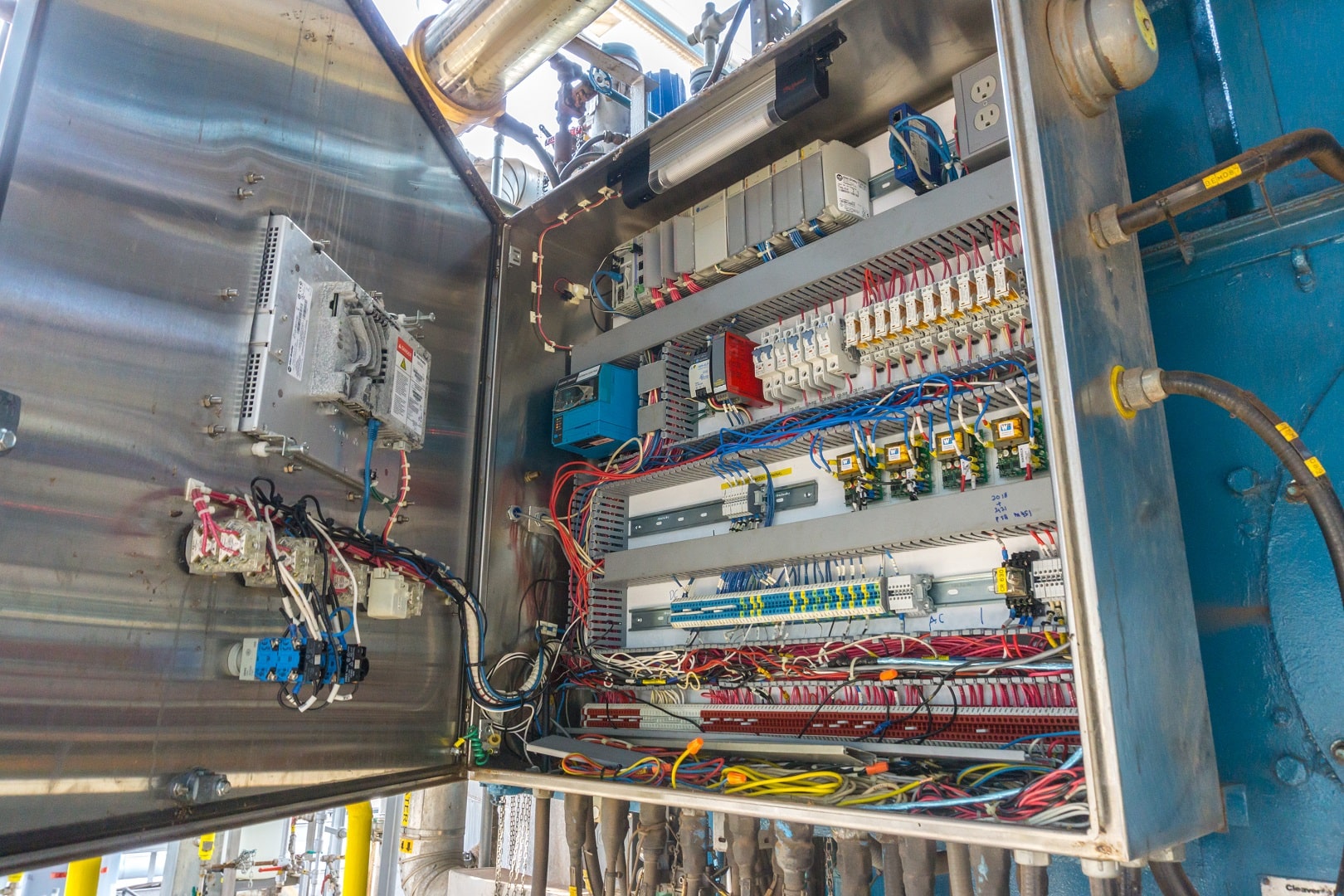

KVM Automation also assembles control panels for distribution systems, power plants, water and waste-water processing plants, chemical plants, manufacturing lines and metal industries. Further, Our scope includes process simulation, PID design, PFD and electrical diagrams. We always meet all relevant national and international standards and utilize the latest, cutting-edge design and manufacturing technologies.

Learn more about KVM Automation projects by contacting one of our specialists. Our pricing and delivery time are competitive in Southern California.

Electrical and Instrumentation Engineering

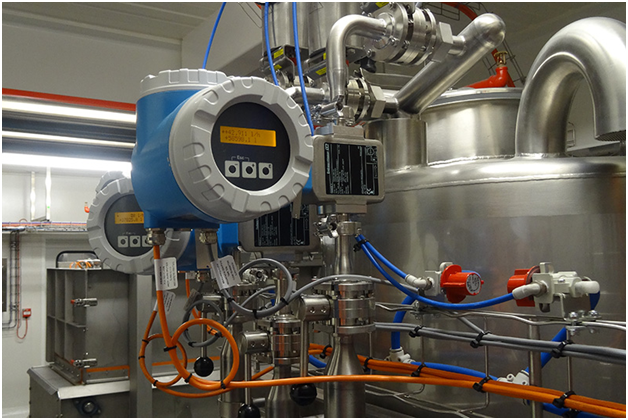

KVM Automation provides the solution to automate or control your new or existing industrial process following your specifications. We offer a wide range of technologies and integration capabilities, including:

- Integrated, Open and PLC-based controls

- Local and wide-area Network

- HMI

- SCADA technology (Supervisory Control and Data Acquisition)

- Power monitoring and energy efficient systems

System Integration

We also provide the consulting and expertise to combine any sub-processes or systems for a total integration solution. Usually, our scopes include feasibility studies, installation and integration of the products, and training and maintenance.

Here are some of the common projects that we offer to our customers in different markets:

- Soft Starter Panels

- Process Control Panel

- Burner Control Systems

Advantages of Industrial Automation

- Increased productivity: Automation systems can reduce manpower requirements and allow higher output without increasing costs.

- Improved quality: Industrial robots are designed with redundant safety features and are programmed to perform tasks with extreme precision, which results in little human error and fewer defects. Additionally, automation systems can help monitor products as they move through the manufacturing process to ensure quality control on an ongoing basis.

- Reduced costs: When an automated system is installed, it requires less maintenance than a comparable manual operation; this leads to lower operating costs over time because less money needs to be invested into repairs or replacements of broken equipment or parts that wear out faster due to heavy use from human operators (e.g., tires). In addition, some types of automation may require less labor during setup time compared with other methods of production like hand crafting where there’s no guarantee about how long certain tasks will take at any given time since people have different levels skillsets between individuals – so much so that some might even take longer than others despite having similar education backgrounds!

How Does Distributed Control System (DCS) Work?

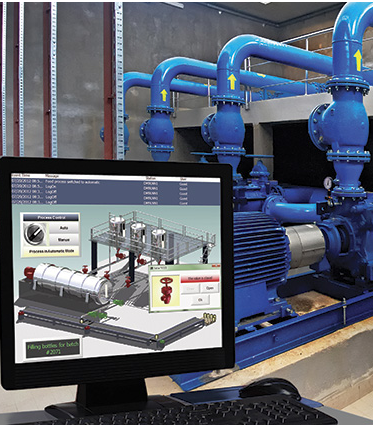

According to Control Station, A distributed control system (DCS) is a network of computers, controllers, operator terminals and field devices that are linked together to control, monitor and optimize the production process.

The DCS is used in industries such as oil and gas, chemical, pharmaceuticals, food and beverage, pulp and paper and power generation.

The main components of DCS are:

- Operator terminals or human machine interfaces (HMI) where operators monitor the status of a system or make changes to it by using multimeter hardware tools.

- Programmable logic controller (PLC): A PLC consists of input/output blocks connected together via programmable wiring harnesses.

These blocks perform logical operations such as functions for switching signals on or off based on various inputs from sensors connected directly or indirectly to their respective I/O ports; timers act as counters that count pulses from an external sensor which then triggers an output event when the counter reaches its preset value; counters record how many cycles have occurred since they were started running; analog-to-digital converters convert analog signals into digital values so they can be processed by other elements within a device without introducing any errors into calculations due to fluctuations in voltage levels between 0V – 5V output range provided by most transducers used today!

Programmable Logic Controller (PLC)

PLCs are the most common type of industrial automation. They can be programmed to control an industrial process, such as a pump or conveyer belt, at predetermined intervals.

A PLC is a special-purpose computer that consists of programmable logic controllers (PLC) and other components to make it work properly. It’s also known as an “electrical brain” because it controls machines and processes in industries like manufacturing, power generation, and oil and gas production.

Variable-Frequency Drives

In accord with, FEECO industries, variable-frequency drives (VFDs) are used to control the speed of an electric motor. They can be applied in a wide variety of applications, including:

Industrial processes such as conveyor systems and material handling equipment

Robotics for automated assembly and packaging operations

Automotive industries—from assembly lines to vehicle testing facilities and showrooms; aerospace industries—from jet engines to spacecraft propulsion systems

Flexible Manufacturing System (FMS)

Flexible manufacturing systems are a type of computer-integrated manufacturing (CIM) technology.

In an FMS, the product is designed and built using a computer-aided design (CAD) system. The CAD system generates a computerized data file that has all the information needed to produce one or more products, such as dimensions and materials required to complete each product.

The data file is then sent to various machines which use this information to cut, grind, drill or mill parts as needed.

Get the Top Notch Industrial Automation Solutions with KVM Automation!

Industrial automation is one of the most important factors in manufacturing growth because it allows companies to produce more goods at lower costs than ever before while also ensuring quality control throughout each step of production. Automation can be used in many different ways depending on what type of business needs it most (small or large). To get the best industrial automation solutions for your industry, just fill out the form below and we’ll get in touch with you shortly!